Tractor Hydraulics Troubleshooting: Your Ultimate Guide

In case you are a farmer, you will agree with me that most of the farm operations such as drafting, tilling among others are dependent on the tractor’s hydraulics. Hydraulics form a very important part of your tractor plus all your machinery, and whenever they fail, operations can stagnate.

In this guide, we’ll explore the role of hydraulic systems in tractors, the types of hydraulics you can expect, some of the problems you may encounter, and a full troubleshooting list.

Tractor Oil Change Kits & Accessories

Get everything you need: filters, funnels, and premium oils in one place.

Shop Kits →As an Amazon Associate, I earn from qualifying purchases.

Why Tractor Hydraulics Are Important

Tractor hydraulics are more like the life blood of your tractor, or in this case the component of the tractor that takes the energy and puts it into a form of motion that can make a number of different tools and attachments work.

This system allows your tractor to perform more than just moving backward and forward such as lifting a heavy load, plowing the fields while using the front-end loader. This makes understanding and maintaining hydraulics a must if you will have to derive the maximum functionality of your machine.

Types of Tractor Hydraulic Systems

Familiarity with a number of kinds of tractor hydraulic systems can be beneficial when fixing and also when selecting the proper hardware. Here are some of the most common types:

1. Open-Center Hydraulic System

An open-center system is one in which the hydraulic fluid circulates through an open loop, regardless of whether or not its actuators are in use. These systems are basic and are normally implemented in the less complex tractors on the field.

They require less maintenance and it is easier to diagnose a problem with the system but the discharge of a closed-center system can be higher.

2. Closed-Center Hydraulic System

Laminated systems are comparatively more complicated and used in behemoth, high horsepower tractors only. This system has demand in which the hydraulic pump is required to circulate the fluid only when the need arises.

This is executed to mean that there is increased efficiency and power to be exercised although it might be more cumbersome to solve the problems that may occur.

Features and Benefits of Tractor Hydraulics

- Efficiency: Hydraulics in tractors facilitate in doing certain jobs which otherwise could be very much tiresome to perform all by hand.

- Precision Control: Hydraulic systems are characterized by high control thus making it easier to perform delicate tasks such as loading and unloading.

- Versatility: Hydraulic system makes a tractor adaptable to many types of implements hence enhances the flexibility of the equipment.

🔧 Hydraulic Repair Essentials

Seal kits, gauges, and UTF fluid to fix leaks and weak hydraulics.

Shop Hydraulic Parts →As an Amazon Associate, I earn from qualifying purchases.

Comparison Table: Open-Center vs. Closed-Center Systems

| Feature | Open-Center System | Closed-Center System |

| Complexity | Simple | More Complex |

| Hydraulic Flow | Continuous | On-Demand |

| Efficiency | Moderate | High |

| Maintenance Needs | Easier | More Challenging |

| Power Output | Limited | Higher |

Popular Tractor Hydraulic Models

- John Deere 1025R Hydraulic System: Personally, this type of gardening is known to be more reliable and efficient as suitable for smallholding farming as well as landscaping.

- Massey Ferguson 4707 Hydraulic System: Can provide a closed center hydraulic system that is extremely suitable for mid to heavyweight agricultural applications.

- Kubota L2501 Hydraulic System: Has an open-center design that is more common among the homeowners and many small farmers thanks to its ease of use and maintenance.

Tractor Hydraulic Troubleshooting: Common Issues and Solutions

Hydraulic issues are not unusual, they can occur on any type of machine and are usually fixable if you can identify the problem. Some of the common challenges that clients face and how to solve them are given below.

1. Hydraulic System Overheating

Possible Causes: Lack of proper fluids in the hydraulic system, low quality of hydraulic oil, blocked up filters, or use of the tractor for work it is not designed to do.

Solution: Take care of fluids on the car and add or change them when they are low. It is recommended that only the best hydraulic oil should be used according to the manufacturer’s recommendation. The filters must not be clogged and should be replaced as often as recommended.

2. Slow Hydraulic Response

Possible Causes: Filter elements plugged, and/or pumps wear or leakage, or internal hydraulic lines abuse or damage.

Solution: There are filters that get blocked up and they should be checked and replaced, the hydraulic lines ought to be checked for any signs of leakage or contractors and the pump pressure should be checked if it needs to be replaced.

3. Noisy Hydraulics

Possible Causes: Orifices, air in the system or loose speaker connections and low levels of hydraulic fluid.

Solution: First, always bleed the hydraulic system to remove the trapped air, then tighten up all the connection, and if the hydraulic fluid levels are low, add more.

4. Erratic Operation

Possible Causes: Dirtied hydraulic fluid, faulty control valves, or wrong hydraulic pressure.

Solution: Scooped out the hydraulic fluid that has been used for a long time and replaced by a clean and fresh one. Control valves must be checked for any form of defect while checking the pressures as well.

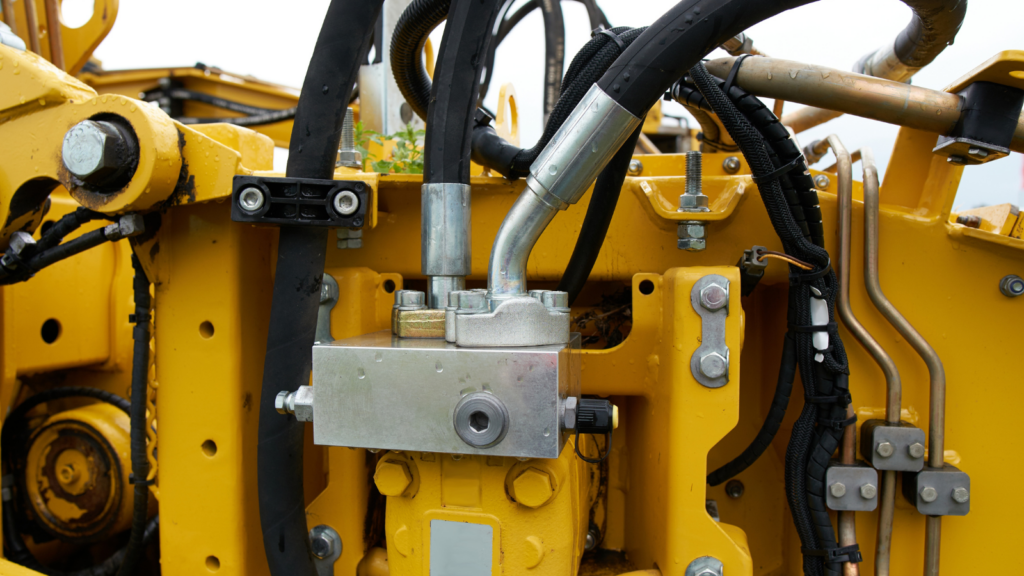

Installation Guide: Step-by-Step Instructions for Installing Hydraulic Systems

If you’re installing a new hydraulic system or replacing an existing one, follow these steps to ensure a successful setup:

- Gather Your Tools: Before starting, ensure you have all necessary tools, such as wrenches, hydraulic lines, and the right hydraulic oil.

- Attach Hydraulic Lines: Securely connect the hydraulic hoses to the tractor’s ports. Make sure all fittings are tight to prevent leaks.

- Install the Hydraulic Pump: If you’re adding a new pump, mount it in the designated area, usually near the engine.

- Connect the Control Valve: Attach the hydraulic control valve, which will allow you to direct fluid to different attachments.

- Fill with Hydraulic Oil: Use the recommended hydraulic oil and fill to the appropriate level.

- Test the System: Once installed, run a test to check for leaks or unusual noises. Make adjustments as necessary to optimize performance.

Maintenance Tips: How to Keep Your Hydraulic System in Optimal Condition

To keep your tractor’s hydraulic system in peak condition, regular maintenance is essential:

- Check Fluid Levels: Always maintain the hydraulic fluid at the recommended level to avoid overheating or inefficient operation.

- Replace Filters Regularly: Clogged filters can cause pressure issues and slow response times. Make it a habit to replace filters as per the manufacturer’s schedule.

- Inspect Hydraulic Hoses: Frequently check hoses for any signs of wear, leaks, or kinks. Replace any damaged hoses immediately.

- Use High-Quality Oil: Poor-quality hydraulic fluid can lead to inefficient performance and wear on components. Always use high-quality oil suited for your system.

- Lubricate Moving Parts: Proper lubrication can reduce wear and prolong the life of the hydraulic system’s moving parts.

Conclusion

Understanding tractor hydraulics troubleshooting can make a significant difference in keeping your machine operational and efficient. The key lies in early diagnosis, regular maintenance, and using the correct hydraulic components to suit your needs.

With this guide, you’ll be better equipped to address hydraulic issues and ensure your tractor continues to serve you well.

If you want to dive deeper into tractor hydraulics maintenance and troubleshooting, you might also find our article on Top Tools Every Tractor Owner Should Have very helpful.

Remember: A well-maintained hydraulic system not only ensures your tractor runs smoothly but also saves you from costly repairs and downtime.