John Deere 420 Clutch: Everything You Need to Know

The John Deere 420 is an economical and reliable lawn and garden tractor with a good working capacity that can be depended upon. But like any machine, it may have features that from time to time may require some form of intervention.

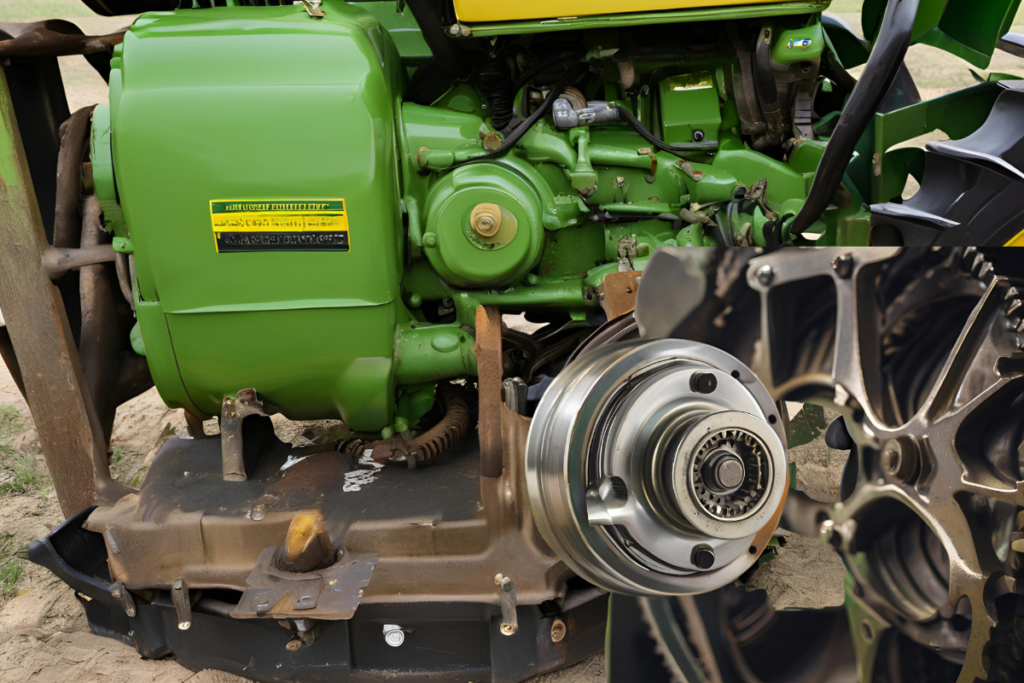

Particularly important here is the so-called PTO (Power Take-Off) clutch. This guide will look at why the John Deere 420 clutch is important, its parts, replacement options, and tips for the installation and care of the clutch.

John Deere 420 Clutch Parts and Accessories

Why the John Deere 420 Clutch Matters

This feature is popularly referred to as the PTO clutch and is used in engaging and disengaging non-power take-off implements such as the mower deck.

By failing to provide an efficient clutch, your tractors can be problematic and challenged in terms operation and output. Proper maintenance of the clutch enhances on the operations of the machine and also enhances the life span of the attachment.

Types of John Deere 420 Clutches

OEM vs. Aftermarket Clutches

If ever there is a need to replace the John Deere 420 clutch, the customer has the two choices: the OEM clutch and the other clutch or the another brand clutch.

Original equipment manufacturer clutches are manufactured by John Deere while aftermarket clutches are by other manufacturers such as Xtreme Outdoor Power Equipment and Steiner Tractor Parts.

- OEM Clutches: Designed specifically for the John Deere 420, ensuring a perfect fit but at a higher price point.

- Aftermarket Clutches: More affordable, widely available, and often come with good performance ratings, although the fit and longevity may vary depending on the brand.

Popular Replacement Models

- Xtreme Outdoor Power Equipment (X0752): Known for durability and affordability.

- Steiner Tractor Parts PTO Clutch: Offers good compatibility with the John Deere 420.

- Stens Electric PTO Clutch: A common choice for users seeking a budget-friendly option.

🔧 John Deere 420 Clutch Parts Kit

Complete clutch repair kits, pressure plates, and pilot bearings for your John Deere 420.

Shop Clutch Parts →As an Amazon Associate, I earn from qualifying purchases.

Common Issues and Troubleshooting

Even the best clutches can face problems over time. Some common issues include:

- Intermittent Function: Users have reported that their PTO clutch works sporadically, often due to wear and tear or poor maintenance.

- Premature Failure: In some cases, users have experienced their clutch breaking shortly after the warranty period expires. This is common with certain aftermarket options.

To avoid these issues, regular inspections and timely replacements are crucial.

Clutch Replacement Components

When replacing the PTO clutch on your John Deere 420, it’s essential to have the complete kit. A typical clutch replacement kit includes:

- Engine Clutch

- Alignment Tool

- Pilot Bearing

- Throw-Out Bearing

- Additional Required Hardware

Having these components ensures that your replacement goes smoothly and that the new clutch fits perfectly.

Comparison Table: OEM vs. Aftermarket John Deere 420 Clutches

| Feature | OEM Clutches | Aftermarket Clutches |

| Price | Higher | Lower to Moderate |

| Fit | Perfect | Varies by Brand |

| Durability | Excellent | Good to Excellent |

| Availability | Limited | Widely Available |

| Warranty | Typically Longer | May Be Shorter |

Installation Guide: Step-by-Step Instructions

Changing the clutch of John Deere 420 can be easily accomplish by anyone who possesses some mechanical abilities. Here’s a simple guide:

- Safety First: Make sure that the tractor is stationary, idle and should be switched off, and does not have any connection to any power source.

- Remove the Mower Deck: This position opens you an easier access of the PTO clutch.

- Disconnect the Old Clutch: After that, it is necessary to remove the old clutch very carefully and the wires and connections must be separated to.

- Install the New Clutch: Properly align the new clutch with the help of alignment tool and tighten it with the help of the hardware provided with clutch.

- Reconnect Wires and Components: Check the spindles and tighten the bolts that holds them and the spindle on the front axle before replacing the mower deck.

- Test the Clutch: Once everything is put back, it is time for a test: engage and disengage the clutch while using your attachments.

For a more detailed guide, check out this installation video.

Maintenance Tips: Keep Your Clutch in Optimal Condition

- Regular Inspections: Look for visible damages, broken wires or signs of improper connection.

- Clean the Clutch Area: Clutches may be affected by dirt and debris hence should be cleaned regularly.

- Lubricate Moving Parts: It is recommended to lubricate the bearings and all the parts that are subject to friction with the right kind of lubes in order to have them last longer.

- Replace Worn Components: The clutch wears out slowly, as mentioned above, thus, use replacement parts as soon as they are damaged extensively.

The John Deere 420 clutch is required to making sure your tractor is running like it should. It does not matter whether you are using OEM or aftermarket clutch; the knowledge of the various choices, how to fit and service them does help a lot.

Proper maintenance and proper replacement of parts will make your John Deere 420 last long and be efficient for years.